Maintaining a self-propelled dredge is essential for its longevity and optimal performance. Regular inspections help catch small issues before they become big problems, leading to greater efficiency and significant cost savings over time. Daily tasks, such as checking oil levels and lubricating moving parts, should be routine to keep everything running smoothly. Also, having a periodic maintenance schedule ensures that critical components are inspected regularly. It’s important to clean the dredge after each use and monitor performance indicators closely. Lastly, don’t hesitate to seek expert advice for complex issues while keeping detailed logs of maintenance activities, this helps track overall health of your dredge!

1. Importance of Regular Maintenance

Regular maintenance is crucial for keeping a self-propelled dredge running smoothly and efficiently. By prioritizing routine checks and care, you not only boost the overall efficiency of the dredge but also significantly lower operational costs over time. A well-maintained dredge is less likely to face major repairs, allowing it to operate longer without interruptions. Frequent inspections help identify potential issues early, preventing costly breakdowns and downtime. Additionally, regular maintenance can improve fuel efficiency and reduce emissions, which is beneficial for both the environment and your budget. Safety is another key aspect; maintaining equipment properly enhances safety for operators and workers in the area. Furthermore, good maintenance practices can increase the resale value of the dredge, making it a smart investment in the long run. Establishing a culture of responsibility and care within your team fosters pride in the equipment and promotes diligent upkeep. Compliance with regulations becomes much easier when you have a solid maintenance routine, ensuring that your operations meet industry standards. Lastly, consistency in maintenance leads to predictable performance, giving you confidence in your dredging operations.

2. Daily and Weekly Maintenance Tasks

Daily maintenance tasks are essential for keeping a self-propelled dredge in top shape. Begin each day with a thorough inspection: check hydraulic fluid levels and look for any leaks that could signal problems. It’s also crucial to examine the electrical systems, ensuring there are no loose wires or signs of corrosion that could lead to failures. Daily cleaning of the deck and working areas not only promotes safety but also helps maintain operational efficiency. Don’t forget to monitor fuel levels daily to avoid interruptions in your work.

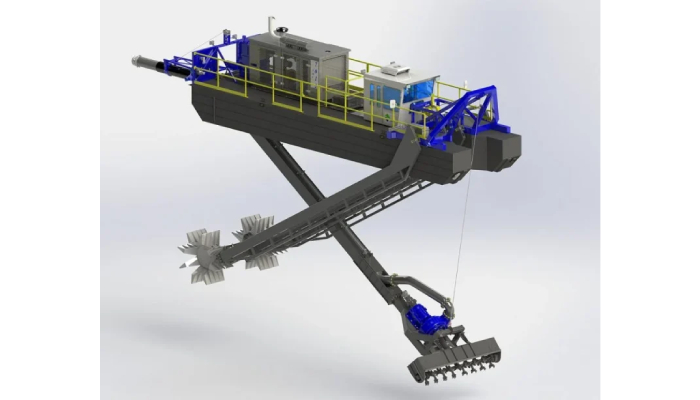

As the week progresses, you’ll want to dive into more detailed checks. Weekly maintenance tasks should include inspecting the hull of the dredge for any signs of wear, as well as examining the dredging arm and its connections. Look for any wear or damage that might affect performance. Additionally, testing safety devices and alarms each week ensures that you are prepared for any emergencies. Also, make it a point to check the condition of the dredge’s navigation and communication systems to keep operations running smoothly. Keeping a daily log of all these checks will create a clear record, helping you stay on top of maintenance and spot any trends or recurring issues.

- Daily inspections should include checking hydraulic fluid levels and leaks.

- Examine electrical systems for loose wires or corrosion.

- Daily cleaning of the deck and working areas is essential to prevent accidents.

- Weekly tasks should also include checking the condition of the dredge’s hull.

- Inspect the dredging arm and its connections for any wear or damage.

- Weekly checks should encompass testing safety devices and alarms.

- Daily logging of all checks helps in maintaining a clear record.

- Monitor fuel levels daily to ensure uninterrupted operations.

- Check the condition of the dredge’s navigation and communication systems weekly.

- Regularly verify that all emergency equipment is functional.

3. Periodic Maintenance Schedule

A well-planned periodic maintenance schedule is vital for the longevity of your self-propelled dredge. Begin with inspections every 100 hours, focusing on cleaning the fuel system components thoroughly. This helps in preventing any fuel-related issues that could compromise performance. At the 250-hour mark, it’s crucial to assess hydraulic lines for any leaks or wear; replacing these as needed can save you from more significant problems down the line. After 500 hours, checking the dredge’s electronic systems and updating software, if applicable, ensures that all components are running smoothly and efficiently. Then, every 1,000 hours, conduct a full structural integrity assessment of the dredge. This is your opportunity to catch any potential weaknesses before they become critical failures.

It’s also wise to schedule major overhauls based on your dredge’s usage patterns and the environmental conditions it operates in. For instance, if you expect harsh weather, consider a seasonal maintenance schedule to prepare your equipment accordingly. Establish a checklist for each maintenance task to ensure no detail is overlooked. Communicating upcoming maintenance needs with your crew well in advance helps in organizing and executing these tasks effectively. Additionally, use maintenance logs to analyze trends over time and adjust your schedules based on the dredge’s performance. Lastly, don’t hesitate to connect with manufacturers for updates on best practices and recommendations tailored to your specific dredge model.

4. Lubrication Practices

Proper lubrication is key to ensuring that your self-propelled dredge operates smoothly and efficiently. Always use the type of lubricant recommended by the manufacturer, as this guarantees compatibility and effectiveness. Developing a lubrication schedule based on the dredge’s usage can help avoid friction damage, which can lead to costly repairs. Make sure all grease fittings are easily accessible for routine maintenance, allowing for quick and hassle-free lubrication. Regularly monitor lubrication levels and refill as necessary to keep moving parts well-protected.

Replacing lubricants according to the manufacturer’s guidelines is crucial, as this prevents sludge build-up that can hinder performance. Opt for high-quality lubricants designed specifically for marine environments, as they offer better protection against the harsh conditions your dredge may face. Training crew members on proper lubrication techniques can enhance the overall maintenance process, ensuring that safety measures are observed. To avoid mix-ups, consider implementing a color-coding system for different lubricants, making it easier to identify and apply the correct one.

Logging lubrication activities is also a smart practice, creating a historical record that can be invaluable for future maintenance decisions. For critical components, think about using automated lubrication systems, which can help optimize the application of lubricants and reduce the risk of human error. With these practices in place, you can significantly enhance the longevity and reliability of your self-propelled dredge.

5. Cleaning and Sediment Management

Cleaning is a vital part of maintaining a self-propelled dredge, ensuring it operates at peak performance. Implement a routine flushing process after each job to wash away sediment and debris, preventing build-up that can hinder efficiency. Create a sediment management plan to monitor and control the flow of sediment, helping to keep your dredging operations smooth and effective. Regularly clean filters and strainers to ensure that your pumps work at maximum efficiency, as clogged filters can lead to reduced performance and costly downtime.

It’s also essential to conduct periodic inspections of the dredge’s intake and discharge points, as these areas can accumulate debris and affect the dredge’s functionality. Use eco-friendly cleaning agents whenever possible to minimize your environmental impact. Training your staff on proper cleaning techniques is crucial, as improper handling can lead to damage and costly repairs.

Keeping a log of cleaning activities can help track effectiveness and pinpoint areas that might need more attention. Additionally, establish best practices for sediment disposal that comply with local regulations, ensuring your operations are environmentally responsible. Don’t forget to monitor for algae growth or other obstructions that could affect performance, and encourage your team to report any cleaning issues immediately. This proactive approach to cleaning and sediment management will contribute significantly to the longevity and reliability of your dredge.

6. Monitoring Performance Metrics

Monitoring the performance metrics of a self-propelled dredge is vital for ensuring its longevity and efficiency. Start by utilizing digital tools that allow you to track performance metrics in real-time, which can give you immediate insights into how your dredge is operating. Identify key performance indicators (KPIs) relevant to your dredging operations, such as pressure, flow rate, and temperature, which will help you gauge the health of your equipment.

Analyzing data trends is crucial for predicting potential equipment failures before they become serious issues. By regularly reviewing performance reports with your crew, you can ensure that everyone is aware of the dredge’s performance and can make informed decisions based on the data. Setting benchmarks for performance and striving to improve them continuously will keep your operations competitive and efficient.

Integrating your monitoring systems with maintenance schedules can streamline your efforts, making it easier to address issues as they arise. Training your staff to interpret these performance metrics will empower them to make proactive adjustments during operation. Additionally, utilizing GPS tracking for your dredging operations can lead to better efficiency, allowing you to optimize your routes and reduce unnecessary wear and tear.

Establishing alerts for when performance metrics fall below acceptable levels ensures that you can act quickly to prevent damage. Finally, regularly updating your monitoring technology keeps you current with advancements, enhancing your ability to maintain your dredge effectively.

7. Managing Corrosion and Erosion

Corrosion and erosion can be the silent enemies of a self-propelled dredge, so it’s crucial to stay vigilant. Regular inspections are key, allowing you to catch any signs of corrosion early on. When you spot an issue, take corrective action immediately to prevent further damage. Using corrosion-resistant materials in critical areas can significantly extend the life of your dredge. Implementing a protective coating program for exposed components adds another layer of defense, shielding them from the harsh environments they often operate in.

Educating your staff on recognizing the early signs of corrosion and erosion is a proactive step that pays off. Scheduling replacements for parts that show heavy erosion is essential to maintain efficiency and performance. Consider using sacrificial anodes, which can absorb corrosion before it affects more critical components.

Documenting your corrosion management actions is important, as it helps you track effectiveness over time. Additionally, evaluating environmental factors, such as salinity or acidity in the water, can help you understand the risks your dredge faces. Communicating with suppliers about the best materials for your specific conditions can provide valuable insights. Finally, establishing a routine for cleaning and protecting metal surfaces from corrosion will ensure your dredge remains in top condition, ready to tackle the toughest jobs.

8. Regular Inspections

Regular inspections are essential for keeping your self-propelled dredge running smoothly and efficiently. Conducting systematic visual inspections of all critical components weekly is a great practice. Use a checklist to ensure every area is thoroughly checked, from impellers to bearings. Involve your team members in this process; it fosters a sense of responsibility and teamwork. Documenting all inspection findings is crucial, as it helps identify patterns over time that can alert you to potential issues before they become serious problems.

Train your staff to recognize abnormal sounds or vibrations during operations, as these can be early signs of trouble. Schedule inspections during off-peak hours to minimize disruption to your dredging operations. If your dredge has hard-to-reach areas, consider incorporating drone technology for a more comprehensive view. Periodically engaging third-party experts for in-depth assessments can provide fresh insights and help maintain high standards.

Regularly update your inspection protocols to align with best practices in the industry. Encourage crew members to report any unusual observations immediately. This proactive approach to inspections not only enhances the longevity of your dredge but also ensures safer and more efficient operations in the long run.

9. Expert Guidance

Building strong relationships with dredging equipment manufacturers is crucial for ongoing support. These partnerships can provide valuable insights and access to specialized resources. Attend training sessions conducted by industry experts to deepen your understanding of dredging practices. Online resources and forums are also excellent for troubleshooting and gathering advice from fellow professionals. Networking with local dredging associations can lead to shared learning opportunities and foster connections that may prove beneficial in your maintenance efforts. If faced with complex issues, such as hydraulic systems or electronics, consider hiring experts who can offer tailored solutions. Staying informed by regularly reviewing industry publications can keep you updated on new techniques and innovations. Schedule routine consultations with experts for condition assessments, and be sure to incorporate their recommendations into your maintenance plans. Encourage your team members to seek expert advice when they encounter challenging tasks to enhance their skills. Participating in workshops and seminars is another great way to stay current and keep your skills sharp.

10. Documentation and Compliance

Keeping detailed records of all maintenance activities is essential for the longevity of your self-propelled dredge. Not only does it provide a reference for future repairs, but it also helps you identify trends and recurring issues. Using digital tools can streamline this documentation process, reducing the chances of errors and making it easier to access information when needed. Compliance with local and federal regulations is non-negotiable. Regularly reviewing these requirements ensures that your operations remain within legal bounds. Training staff on the importance of accurate documentation is crucial; it fosters a culture of accountability and diligence. Establishing a clear filing system for maintenance records will help everyone know where to find important information. Incorporating documentation into daily processes can make it a habitual practice, ensuring no detail gets overlooked. Utilizing checklists can also help capture all necessary information, making the documentation process more efficient. Conduct regular audits of your maintenance records to confirm their accuracy, which can prevent misunderstandings and mismanagement. Finally, sharing compliance updates with your team keeps everyone informed and promotes a collective responsibility for maintaining standards.