When selecting a butterfly valve manufacturer, it’s important to know what key features to expect that can greatly influence your project’s success. First, a solid understanding of butterfly valves is crucial; these quarter-turn devices play an essential role in liquid flow control across various industries like water treatment and food processing. Next, look for manufacturers who use high-quality materials like stainless steel or cast iron tailored to specific applications. Certifications and compliance with industry standards also hold great importance for safety and reliability. Additionally, seek technical expertise, customization options, and comprehensive product ranges to ensure you find the perfect fit for your needs while enjoying strong customer support along the way.

1. Understanding Butterfly Valves

Butterfly valve manufacturer are fascinating devices that control fluid flow with a simple yet effective mechanism. They operate by using a disc that rotates around a central axis, allowing for fast and efficient flow management. One of their standout features is their compact design, which makes them perfect for tight spaces in piping systems. This quarter-turn operation is not only quick, but it also makes them ideal for automated systems where rapid response is crucial. Additionally, these valves can handle a broad range of pressures and temperatures, making them versatile for various applications, from water treatment to industrial processes.

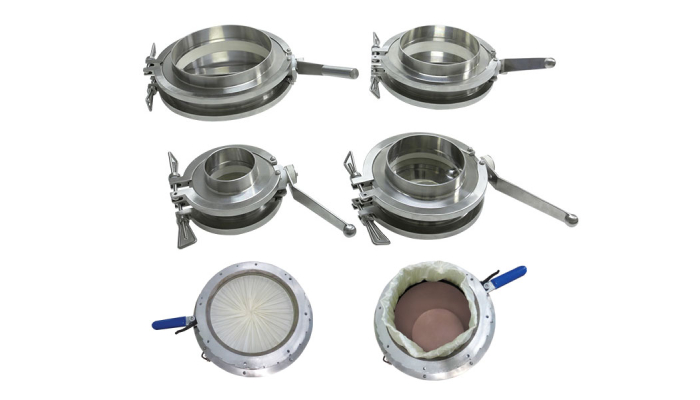

Moreover, butterfly valves are generally lighter than many other valve types, which can significantly reduce the overall weight of piping systems. While they are primarily used for on-off applications, they can also be employed for throttling flow, offering flexibility in operation. Their straightforward design leads to lower manufacturing costs, making them an economical choice for large-scale projects. Maintenance is also a breeze, as these valves are typically easy to manage over time. With various configurations available, such as double-flanged and wafer types, you can find the right fit for different piping systems. Understanding the specific fluid dynamics of your application is key to selecting the ideal butterfly valve, ensuring optimal performance wherever they are installed.

2. Quality of Materials Used

The materials used in butterfly valves play a crucial role in their overall performance and durability. High-quality materials, such as stainless steel, cast iron, and PVC, are essential for ensuring that the valves can withstand the demands of their specific applications. For instance, stainless steel valves are highly resistant to rust and corrosion, making them perfect for industries like food and pharmaceuticals where hygiene is paramount. On the other hand, cast iron valves are well-known for their strength and durability, making them ideal for heavy-duty industrial applications.

PVC butterfly valves are lightweight and excel in resisting chemical corrosion, making them a great choice for water treatment facilities. Bronze and brass, often used in lower-pressure systems, offer robust properties that can enhance longevity and reliability in less demanding environments. It’s important that the manufacturer provides detailed information about material certifications, as this transparency ensures quality assurance.

Additionally, choosing the right material impacts the valve’s lifespan and operational efficiency, so compatibility with the specific fluids in your system is vital to prevent material degradation. The finish of the material, whether it be powder coating or passivation, can also significantly enhance corrosion resistance, providing an extra layer of protection. Finally, consider the environmental conditions in which the valve will operate, as this will further guide your material selection to ensure optimal performance.

3. Certifications and Compliance Standards

When selecting a butterfly valve manufacturer, it is vital to consider their certifications and compliance with industry standards, which are essential for ensuring product safety and reliability. Look for ISO certification, as it signifies adherence to international quality management standards, ensuring the manufacturer maintains high production quality. For applications in the oil and gas sector, API standards are crucial, guaranteeing that the valves meet operational safety requirements. If the valves are intended for food processing or pharmaceuticals, FDA compliance is non-negotiable, ensuring that materials are non-toxic and safe for use. Additionally, CE marking indicates compliance with European safety standards, adding another layer of assurance. Manufacturers should provide proper documentation proving compliance with these relevant standards, as verification helps avoid legal issues and costly product recalls. Third-party testing can further enhance a manufacturer’s credibility, confirming their adherence to these standards. Remember, regular audits and inspections are often necessary to maintain certification status, so a manufacturer committed to compliance will be transparent about their processes. Understanding the significance of these certifications is not just beneficial; it is crucial for guiding you toward selecting a reliable manufacturer that meets your specific needs.

- Manufacturers should comply with industry standards to ensure product safety and reliability.

- ISO certification indicates adherence to international quality management standards.

- API standards ensure that valves are suitable for oil and gas applications, providing operational safety.

- FDA compliance is critical for valves used in food and drug processing industries to ensure non-toxicity.

- Look for CE marking which indicates compliance with European safety standards.

- Manufacturers should provide documentation proving compliance with relevant standards.

- Verification of certifications helps in avoiding legal issues and product recalls.

- Third-party testing can enhance credibility by confirming compliance with standards.

- Regular audits and inspections may be performed to maintain certification status.

- Understanding the significance of various certifications can guide you in selecting a reliable manufacturer.

4. Technical Expertise and Support

When working with a butterfly valve manufacturer, technical expertise and support are essential. The manufacturer should have knowledgeable staff ready to assist with technical questions and help you select the right valve for your specific needs. Access to detailed product specifications and data sheets is crucial, as this information aids in making informed decisions. Additionally, the manufacturer should offer guidance on installation and maintenance procedures, ensuring that you can operate the valves efficiently and safely.

Training resources like webinars and manuals can also be invaluable, helping users understand the best practices for valve operation. A responsive customer service team can address any issues that arise quickly and efficiently, minimizing downtime. It’s especially beneficial if the manufacturer has technical expertise in your specific industry, as this can lead to better recommendations for unique applications.

Having engineers available for consultation can significantly enhance project outcomes, particularly when selecting the right actuator type to optimize valve performance. The manufacturer should be open to collaborating on custom solutions for complex systems, ensuring that the valves fit seamlessly into your operations. Lastly, access to troubleshooting guidance can be a lifesaver during operational issues, helping you get back on track without unnecessary delays.

5. Comprehensive Product Range Offered

A top-notch butterfly valve manufacturer should boast a diverse product line that caters to various needs. This allows customers to find all necessary components from a single supplier, simplifying the procurement process. Different types of butterfly valves, such as wafer, lug, and flanged designs, are crucial for addressing specific applications and requirements. Additionally, having a variety of sizes ensures compatibility with different piping systems, making it easier to integrate valves into existing setups.

Moreover, specialized valves, such as high-performance or sanitary designs, can meet unique industry needs, whether in food processing or chemical handling. A range of actuator options, including manual, electric, and pneumatic, further enhances the versatility of the offerings, allowing users to choose the best fit for their operational requirements.

It’s also beneficial when manufacturers consider related products, such as accessories and fittings, as this can streamline the procurement process, reducing the time and effort needed to source multiple components. An up-to-date product catalog that showcases the latest technologies and innovations is essential, as this ensures customers have access to cutting-edge solutions.

In some cases, custom valve designs may be critical for unique applications that go beyond standard sizes. This flexibility can be a game-changer for projects with specific demands. Ultimately, a comprehensive range of solutions from a single manufacturer can significantly streamline project timelines and logistics, making the entire process more efficient and hassle-free.

6. Customization Options for Specific Needs

Customization is key when working with a butterfly valve manufacturer, as it allows you to tailor the valve to meet your exact requirements. This ensures that the valve fits seamlessly into your unique system, whether that means selecting materials that withstand specific environmental conditions or adjusting the size to fit tight spaces. Additionally, the choice of actuator type should align with the operational demands of your system, providing the right balance of speed and control.

Specialized options like custom seals and coatings can significantly enhance performance in harsh environments, ensuring long-lasting durability. It’s also crucial to consider specific pressure ratings to guarantee that the valve can handle the operational loads expected in your application. Design modifications can be made to accommodate unique piping configurations, offering flexibility that can adapt to future system changes.

Collaboration with engineers during the customization process can lead to better outcomes, ensuring that the valves are not only functional but also optimized for efficiency. Furthermore, having the ability to specify testing conditions helps ensure that the valve performs as expected under various scenarios, providing peace of mind that your investment is sound.

7. Performance and Reliability Expectations

When working with a butterfly valve manufacturer, performance and reliability are at the forefront of your expectations. First and foremost, these valves should deliver a tight seal, effectively preventing any leakage during operation. This is critical for maintaining system integrity and safety. Additionally, durability is essential; the valves must withstand varying pressure and temperature extremes without compromising their function.

Long service life is another expectation, as it can significantly reduce the frequency and costs of maintenance. A manufacturer should prioritize performance testing as part of the production process, ensuring that each valve meets high-quality standards.

It’s also important that the valves facilitate flow regulation without causing a significant pressure drop, which can impact system efficiency. Reliability across different operating conditions is key, as it ensures consistent performance regardless of environmental factors.

A reputable manufacturer will typically offer warranty options that reflect their confidence in the product’s reliability. Furthermore, feedback from previous customers can provide valuable insights into real-world performance, helping you gauge potential issues before making a purchase.

In automated systems, the valve’s response time is crucial, so manufacturers should consider this aspect as part of their design and testing processes. Lastly, regular performance assessments can help maintain optimal operation, ensuring that your butterfly valves continue to function effectively over time.

8. Lead Time and Availability Considerations

When working with a butterfly valve manufacturer, lead time and availability can make or break your project timeline. Efficient production and shipping processes are key, as they minimize delays that could hinder your operations. Manufacturers with local warehouses are particularly valuable, as they can significantly reduce lead times for urgent requests, allowing for quicker access to the valves you need. It’s essential for manufacturers to provide clear timelines for order fulfillment, so you’re never left in the dark about when to expect your products.

Stock availability of standard products is another crucial factor, ensuring that you can access what you need without unnecessary wait times. If you’re planning bulk orders or entering into long-term contracts, it’s worth discussing lead time options, as manufacturers may offer better timelines for larger commitments. This is especially important during emergencies or shutdowns, where timely delivery is critical to keep operations running smoothly.

Transparent and proactive communication regarding order status helps manage expectations and allows for better planning. Flexibility in order adjustments can also aid in accommodating changing project needs, ensuring that you can adapt without significant delays. Manufacturers with established logistics networks often ensure reliable delivery schedules, which enhances trust and reliability in their service.

Finally, understanding potential delays in supply chains can greatly assist in planning and risk management, helping you to navigate any unforeseen challenges that may arise.

9. Customer Support and Service Quality

Customer support can make all the difference in your experience with a butterfly valve manufacturer. Excellent service enhances the overall purchasing experience, providing you with the confidence that help is just a call away. When issues arise, responsive service is key, allowing for quick resolutions that minimize downtime, which is crucial for any operation. Technical assistance should also be readily available for installation and troubleshooting, ensuring that you can set up your valves correctly and efficiently.

Regular communication and follow-ups demonstrate a commitment to customer satisfaction and can foster long-term relationships. Having access to online resources, like FAQs and installation guides, makes it easier for you to find solutions on your own and enhances your understanding of the product. After-sales support is vital for ongoing maintenance and service needs, allowing you to keep your operations running smoothly.

A manufacturer that values customer feedback can continually improve its service quality over time, making sure that your voice is heard. Additionally, training sessions or workshops can empower you to use the products effectively, giving you the knowledge you need to maximize their potential. Finally, having local service representatives can enhance accessibility, making it even easier to get the support you need when you need it. All of these elements contribute to a strong support network, leading to greater customer satisfaction and loyalty.

10. Cost Considerations for Long-Term Value

When considering the cost of butterfly valves, it’s important to look beyond the initial price tag. A high upfront cost might raise eyebrows, but investing in quality valves can lead to significant savings over time. Think about the total cost of ownership, which includes not just the purchase price but also installation, maintenance, and operational costs. For example, a durable valve that requires less frequent repairs can minimize downtime and related expenses, making it a smarter choice in the long run.

Long-term warranties can serve as a strong indicator of a manufacturer’s confidence in their product’s quality and performance. These warranties not only protect your investment but also offer peace of mind. Furthermore, analyzing lifecycle costs can illuminate the financial impact of your decisions, helping you to see the true value of each option.

Don’t overlook potential savings from bulk purchases, either. If you have a larger project, buying in bulk can lead to impressive discounts. Regular maintenance is another key factor; a well-maintained valve can last significantly longer, enhancing its overall value. Lastly, consulting with industry experts can provide you with valuable insights into cost-effective solutions that align with your specific needs. By prioritizing value over mere price, you can make informed decisions that positively impact your bottom line.