manufacturing plantsWhen it comes to modern industrial and manufacturing operations, efficiency and safety are paramount. One of the most valuable pieces of equipment that businesses rely on today is the mobile column lift. These sophisticated machines have revolutionized the way companies handle equipment positioning and vertical transport, making them indispensable in warehouses, assembly lines, and service facilities across the globe.

A mobile column lift is an advanced hydraulic lifting system designed to raise, lower, and position heavy equipment safely and precisely. Unlike traditional lifting equipment, these systems are mobile, allowing operators to move them to different locations within a facility with ease. The device consists of multiple synchronized vertical columns that work together to provide stable and balanced lifting capabilities. Each column operates independently with its own hydraulic system, ensuring that even if one unit experiences an issue, the others continue to function. This redundancy feature makes mobile column lifts extremely reliable and safe for handling loads that can range from several thousand to over a hundred thousand pounds. The lift platforms are typically equipped with digital controls and safety features that allow operators to adjust heights with precision, making them ideal for a wide variety of applications in industrial settings. These systems have become a standard requirement in many manufacturing facilities, automotive shops, and warehouses where heavy equipment needs to be moved vertically and positioned accurately.

Understanding Mobile Column Lift Technology

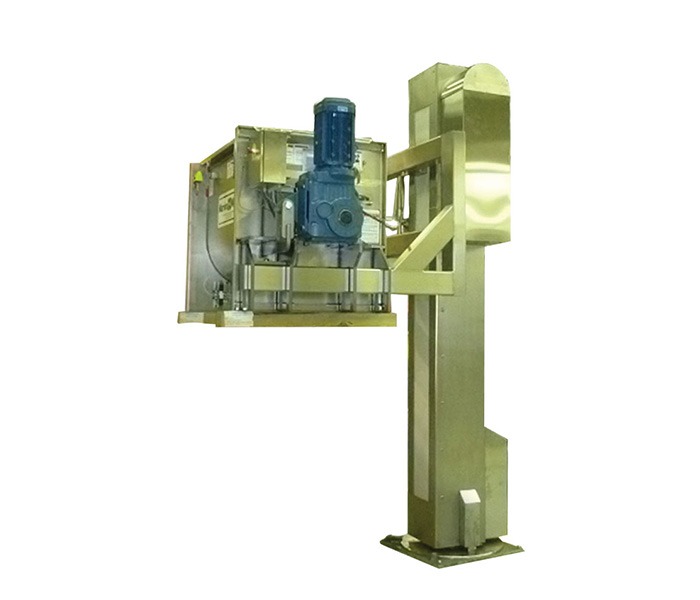

The technology behind a mobile column lift is quite sophisticated and involves several key components working in harmony. The hydraulic pump serves as the heart of the system, providing the necessary pressure to lift heavy loads. Modern mobile column lift systems utilize synchronized hydraulic cylinders that ensure balanced lifting across all columns, preventing any tipping or uneven weight distribution. The control system typically features load cells that monitor the weight being lifted in real-time, automatically adjusting pressure to maintain safety parameters. One of the most advanced features is the mobile equipment positioner, which allows for precise angular and positional adjustments. The entire assembly sits on a sturdy base with wheels or casters, making it mobile enough to move around the facility. Safety interlocks prevent operation if any column detects an abnormality, and emergency descent systems allow controlled lowering even in case of power failure. The synchronization technology ensures that all columns rise and fall at exactly the same rate, which is critical for maintaining the integrity of the load being lifted. These technological advancements have made mobile column lifts not just convenient tools but essential safety equipment in modern industrial operations.

How Do Mobile Column Lifts Improve Workplace Safety?

How Do Mobile Column Lifts Improve Workplace Safety?

Safety is the primary concern in any industrial environment, and mobile column lifts address this concern comprehensively. By eliminating manual lifting and reducing operator physical strain, these systems significantly decrease the risk of workplace injuries. The synchronized lifting mechanism prevents uneven weight distribution that could lead to accidents or equipment damage. Load monitoring systems ensure that the machine never exceeds its rated capacity, and if there’s any imbalance detected, the system automatically halts operation. The automated controls reduce human error, which is a major factor in workplace accidents. Emergency lowering systems allow safe descent of heavy loads even during power outages, preventing potentially catastrophic failures. Operators maintain a safe distance from the load during lifting operations, and the entire process is monitored by sensitive safety interlocks. The stability provided by multiple synchronized columns means that even in case of a single column malfunction, the load remains safely supported by the remaining columns. Additionally, many modern systems include backup hydraulic circuits and redundant safety mechanisms. The precision controls allow operators to position loads gently and accurately, reducing impact and sudden movements that could cause injury. These comprehensive safety features have made mobile column lifts an essential component of modern workplace safety protocols.

Applications and Industries Relying on Mobile Column Lifts

Mobile column lifts have become essential equipment across numerous industries and applications. The automotive industry uses these systems extensively for vehicle assembly, maintenance, and heavy component positioning on assembly lines. Aerospace manufacturing relies on mobile column lifts for positioning large fuselage sections and assembly of complex aircraft components. Pharmaceutical and chemical facilities use them to safely handle heavy containers and equipment that require precise positioning. Automotive service centers and independent repair shops depend on mobile column lifts for routine maintenance and heavy repair work. Warehouse operations use them for moving and organizing heavy loads, improving both safety and efficiency. Manufacturing plants across industries benefit from their ability to position machinery and components with precision. The aerospace and defense industries particularly value their stability and accuracy for handling sensitive equipment. Food processing facilities use mobile column lifts for handling heavy machinery and hygiene-critical equipment positioning. Electrical utilities employ them for positioning heavy transformers and power distribution equipment. General manufacturing operations across sectors have recognized the productivity gains and safety improvements that mobile column lifts provide. The flexibility of these systems makes them adaptable to nearly any industrial setting where heavy equipment needs to be lifted, lowered, or positioned with precision and safety.

What Factors Should You Consider When Choosing a Mobile Column Lift?

Selecting the right mobile column lift system for your facility requires careful consideration of several critical factors. First, determine the maximum load capacity you need, accounting for potential future growth and unexpected heavy items. Consider the lifting height requirements and ensure the system can accommodate your workspace dimensions. Evaluate the footprint of the lift and confirm that your facility has adequate space for installation and operation. Power requirements should be checked against your facility’s electrical capacity to avoid costly upgrades. Look for systems with synchronization accuracy within acceptable tolerances for your applications. Consider the control system interface and ensure operators can be trained effectively. Check the warranty coverage and after-sales support offered by manufacturers. Evaluate the maintenance requirements and availability of service technicians in your area. Consider the portability features and ensure the lift can be easily moved between different work stations if needed. Look for safety certifications and compliance with relevant industrial standards and regulations. Assess the responsiveness of the manufacturer’s technical support team. Consider whether you need specialized features like tilt functions or extra-wide platforms. Compare the total cost of ownership including purchase price, installation, maintenance, and training. Investigate the reputation and track record of manufacturers in your industry. These considerations will help you choose a system that perfectly matches your operational needs and provides the best long-term value.

Conclusion

Mobile column lifts have become indispensable equipment in modern industrial operations, providing a combination of safety, efficiency, and precision that no other lifting system can match. From automotive manufacturing to pharmaceutical facilities, these systems have proven their value across diverse industries and applications. The advanced hydraulic technology, synchronized operation, and comprehensive safety features make them the preferred choice for businesses that cannot afford downtime or safety compromises. As industries continue to evolve and equipment becomes heavier and more complex, the demand for reliable mobile column lift systems will only increase. Investing in a quality mobile column lift system today is not just about meeting current operational needs but also preparing your facility for future growth and challenges. Whether you are running a small repair shop or managing a large manufacturing facility, choosing the right mobile column lift system with proper training and maintenance protocols will ensure years of safe and efficient operations. The initial investment in these systems pays dividends through reduced workplace injuries, improved productivity, and operational reliability that modern businesses depend on.These considerations

How Do Mobile Column Lifts Improve Workplace Safety?

How Do Mobile Column Lifts Improve Workplace Safety?