To avoid common mistakes with drum handling equipment, start by understanding the risks involved, as improper handling can lead to serious injuries like fractures and back strains. Always conduct a pre-movement checklist: inspect the drum for leaks or warping and plan your route carefully to identify potential hazards. Use appropriate lifting tools instead of manual labor whenever possible – tools like dollies and tippers are essential for safely moving heavy drums. Ensure that all equipment is functional before use, and prioritize safety training for employees to reinforce proper techniques. Lastly, develop clear emergency procedures for spills to protect everyone on site.

1. Understand the Risks of Drum Handling

When handling drums, it’s crucial to recognize the potential injuries that can occur. Common injuries include fractures, lacerations, back strain, and even hernias. These injuries often arise when moving or decanting drums, which can weigh between 400 to 600 pounds. It’s not just about the weight; the contents of the drums can present serious health hazards too. If they contain flammable, corrosive, or toxic materials, improper handling can lead to severe health risks.

Ergonomics plays a significant role in drum handling. Lifting and moving heavy drums without proper techniques can result in chronic injuries that linger long after the initial incident. Additionally, environmental factors like wet or slippery floors can heighten the risk of accidents. It’s also vital to be cautious of falling hazards when stacking drums or navigating confined spaces where they are stored.

Effective communication among team members is essential to prevent accidents. Everyone involved in the handling process should be aware of their roles and the specific risks at hand. Furthermore, understanding legal requirements and regulations regarding hazardous materials is paramount for ensuring compliance and safety.

Different types of drums, whether plastic or metal, come with unique handling needs. Being informed about these specifics can make a significant difference in safety. Lastly, poorly maintained drum handling equipment can lead to malfunctions, increasing the likelihood of accidents. Fostering a safety culture where employees feel empowered to report hazards and suggest improvements is fundamental to effective drum handling.

- Identify common injuries associated with drum handling, which typically include fractures, lacerations, and back strain.

- Recognize the potential health hazards related to the contents of drums, especially if they contain flammable, corrosive, or toxic materials.

- Understand the ergonomic risks involved in lifting and moving heavy drums, as improper techniques can lead to chronic injuries.

- Consider environmental risks, such as wet or slippery floors, which can increase the chances of accidents during drum handling.

- Be aware of potential falling hazards when stacking drums or working in confined spaces where drums are stored.

- Recognize the importance of clear communication among team members during drum handling to prevent accidents.

- Know the legal requirements and regulations regarding the handling of hazardous materials and ensure compliance at all times.

- Stay informed about the specific risks associated with different types of drums, such as plastic versus metal, and their unique handling needs.

- Be aware of the risks posed by poorly maintained drum handling equipment, which can lead to malfunctions and accidents.

- Encourage a culture of safety where employees feel comfortable reporting hazards and suggesting improvements.

2. Create a Pre-Movement Checklist

Creating a pre-movement checklist is essential for safe drum handling. Start by verifying the drum’s label and contents to ensure you have the correct drum for your task. Before lifting or rolling, check the stability of the drum, making sure it is upright and secure. Evaluate the area where the drum will be moved, identifying the safest path that is free of obstructions and hazards. It’s crucial to confirm that the drum handling equipment is suitable for the weight and type of drum being moved to avoid accidents. Inspect the ground or surface where the drum will be transported, looking for any uneven or unstable areas that could pose a risk. Additionally, review emergency procedures for spills or accidents that might occur during the movement. Ensure that everyone involved is aware of their roles and responsibilities to facilitate a smooth operation. Don’t forget to verify that all team members are wearing the appropriate personal protective equipment, such as gloves and safety footwear, before starting the movement. Lastly, consider any potential environmental factors, like wind or rain, that could impact the process. Document any issues identified during the checklist to enhance future handling practices.

3. Learn Proper Handling Techniques

Proper handling techniques are crucial for ensuring safety and efficiency when working with drums. First, always practice the correct posture when lifting. Keep your back straight and use your legs to support the lift, which helps prevent back strain. When rolling a drum, learn to use gravity to your advantage while maintaining control at all times; this reduces the effort required and minimizes risk.

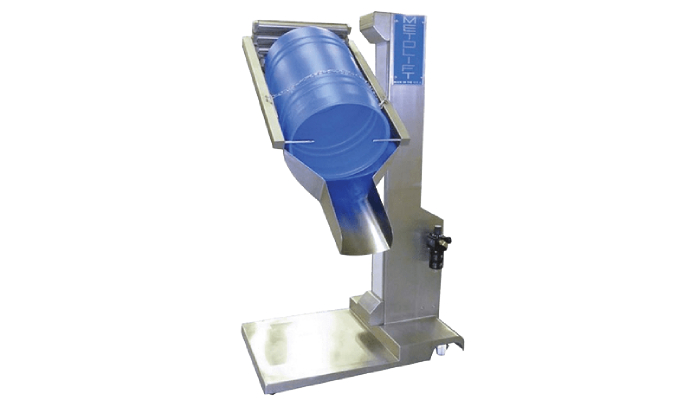

It’s also essential to understand the importance of using your body weight when pushing a drum, rather than relying solely on muscle strength. When maneuvering large drums, familiarize yourself with using a drum dolly or hand truck to make the task easier without heavy lifting. Remember to keep your hands and feet clear of the drum’s path to avoid pinch points and potential accidents.

When stacking drums, ensure they are stable and secure to prevent tipping over. Effective communication is key; develop skills for coordinating with team members during lifts or movements to enhance safety. Always be aware of the signs of fatigue and take breaks when necessary to avoid injuries from overexertion. Maintaining a clear line of sight while moving drums is vital for avoiding collisions, so be alert to your surroundings. Lastly, familiarize yourself with the various types of drum handling equipment and the specific techniques for each, ensuring you are fully prepared for any task.

4. Use Drum Handling Equipment Safely

Using drum handling equipment safely is crucial for preventing accidents and injuries. First and foremost, always check the weight capacity of the equipment before use. Ensure it matches the drum’s weight to avoid overloading, which can lead to malfunctions. Before starting work, inspect the equipment for signs of wear or damage, like rust, cracks, or loose parts. This simple step can save you from serious accidents. Following the manufacturer’s instructions is key; they are there for a reason and can help you avoid misuse.

Adjust the equipment to your height to reduce strain while working. Using appropriate lifting aids, such as forklifts or hoists, is essential when handling heavy drums. These tools can dramatically lower the risk of injury. Remember to keep your work area organized and free of clutter; it allows for safe movement and reduces the chances of tripping.

When maneuvering equipment, use proper techniques, including turning slowly and avoiding sudden movements. If you notice any malfunctions during use, notify your supervisor immediately. Lastly, participate in regular maintenance checks to keep your drum handling tools in optimal condition. A well-maintained tool performs better and keeps everyone safer.

5. Focus on Injury Prevention Strategies

Focusing on injury prevention strategies is key to creating a safe drum handling environment. Start by conducting regular safety audits in the drum handling area to identify and address potential hazards. Encourage employees to speak up about unsafe practices or conditions, ensuring they feel safe reporting issues without fear of retaliation. Implementing stretching and warm-up routines before lifting heavy drums can significantly reduce the risk of injuries. Additionally, promote the use of ergonomic tools that minimize strain on the body during handling tasks, making the process safer and more efficient.

Provide accessible resources for employees to learn about injury prevention techniques specifically related to drum handling. Establish a system for reporting injuries or near misses, which helps identify trends and implement preventive measures. To strengthen the culture of safety, incorporate team-building exercises focused on safe lifting and moving techniques. Clear communication is essential, so establish a signaling system for drum moves to avoid confusion and accidents. Ensure that first aid kits and emergency supplies are readily available and accessible in the work area, so help is always close at hand. Finally, regularly review and update safety protocols to reflect new information or operational changes, keeping safety at the forefront of your drum handling practices.

6. Emphasize Training and Safety Culture

Creating a strong training and safety culture is vital for effective drum handling. Start by developing a comprehensive training program that covers all aspects of drum handling, from safety protocols to proper equipment use. Hands-on training sessions are especially beneficial, allowing employees to practice techniques in a controlled environment. Engaging employees in the creation of safety training materials not only enhances their understanding but also boosts their commitment to safety practices.

Regular refresher courses are essential to keep safety practices fresh in everyone’s mind. Consider implementing mentorship programs where seasoned employees guide newcomers, sharing their knowledge of safe handling practices. Visual aids like posters and instructional videos can serve as constant reminders of safe behaviors in the workplace.

Establishing a safety committee that includes employees from various levels fosters a collaborative approach to safety discussions, helping to identify areas for improvement. Recognizing and rewarding teams or individuals who demonstrate exceptional safety practices can inspire others to follow suit. Hosting safety awareness events or workshops keeps safety at the forefront of everyone’s mind, creating an engaging environment for continuous learning. Remember to gather feedback regularly from employees about the training’s effectiveness, allowing for ongoing adjustments to enhance safety culture.

7. Prepare for Emergency Procedures

Establishing clear emergency response plans is vital for any workplace that handles drums. These plans should specifically address potential incidents like spills or leaks, ensuring that everyone knows the steps to take in case of an emergency. Regular drills are essential; they not only help practice these procedures but also ensure all employees are aware of their specific roles. In case of an incident, easy access to emergency contact numbers and procedures can make a significant difference in response time.

Training is crucial. Ensure that all team members know how to use spill kits and other emergency response equipment available on-site. Designating specific individuals to manage emergency situations is also important, and these individuals should receive thorough training. A clear communication plan for alerting staff during emergencies, including alarms or signals, can help maintain order and prevent panic.

Regularly reviewing and updating emergency procedures can keep them relevant, especially if there are changes in operations or regulations. Implementing an incident reporting system allows you to document emergencies, which can lead to improved responses in the future. Additionally, make sure that all employees know where emergency exits and safety equipment, like fire extinguishers, are located. Encouraging a calm demeanor during emergencies fosters a culture of safety and preparedness, enhancing overall workplace security.