Handling drums safely is essential in preventing injuries and accidents. First, understanding your drum handling equipment is key, as these containers can weigh hundreds of pounds. Always employ tools like drum dollies, lifters, and tippers designed for the specific type of drums you are using. Wearing appropriate personal protective equipment ensures safety against leaks or spills during handling. Regularly inspect all drums for damage and ensure they are securely closed before moving them; clear pathways as well to avoid obstacles that can lead to mishaps. Avoid manual lifting whenever possible; use proper equipment instead and consider training sessions for employees on safe practices for the best results.

1. Understanding Drum Handling Equipment

Drum handling equipment plays a pivotal role in ensuring safety and efficiency in the workplace. Drums, typically ranging from 55 to 85 gallons, can weigh hundreds of pounds, making it essential to use the right tools for lifting and transporting them. The material of the drum, whether steel, plastic, or fiber, also influences the handling method, as each material may require different equipment and techniques. For instance, steel drums might necessitate more robust lifting gear compared to lightweight plastic ones.

Utilizing drum handling equipment such as hoists, lifts, and automated systems significantly reduces the physical strain on workers, thereby lowering the risk of injuries. It’s crucial that this equipment meets industry standards and undergoes regular maintenance to ensure safe operation. Understanding the center of gravity of a drum is vital when lifting or transporting, as it ensures stability and prevents accidents.

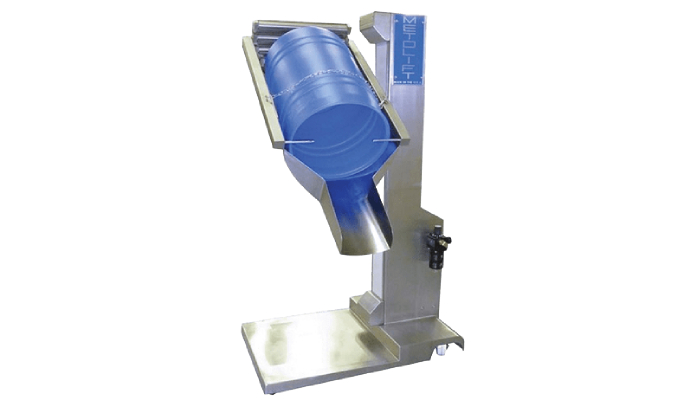

When dealing with drums, the contents inside are equally important to consider, especially if they contain hazardous materials. This requires additional precautions and specialized equipment to handle safely. Familiarizing workers with the various types of drum handling equipment available on the market can enhance their ability to operate safely and efficiently. For example, using drum dollies for movement or tippers for controlled emptying can streamline operations.

Moreover, proper training on the correct techniques for using drum handling equipment is essential. This not only improves safety but also boosts overall productivity. Keeping training materials up to date with the latest technologies ensures that staff remains informed and capable of using the equipment effectively.

2. Essential Safety Measures for Drum Handling

When it comes to drum handling, safety should always be the top priority. Start by conducting a thorough risk assessment of your workspace. This helps identify any potential hazards that could arise when handling heavy drums. Once you have a clear understanding of the risks, implement a safety checklist that includes regular equipment inspections and area checks to ensure everything is in proper condition.

Using proper lifting techniques is crucial, too. Always bend at the knees and keep your back straight when lifting drums, as this minimizes the risk of injury. In areas where drums are stored or handled, establish clear signage to alert workers about potential hazards. This simple step can significantly increase awareness and safety.

Another vital aspect is having a protocol in place for reporting safety issues or equipment malfunctions immediately. Workers should feel empowered to speak up about concerns without fear of repercussions. Additionally, ensure that all staff members are trained in first aid and know emergency contact numbers, just in case accidents happen. Having a well-stocked first aid kit nearby for quick access can make a world of difference in emergency situations.

Regularly reviewing safety policies and adjusting them based on feedback and incident reports is essential for continuous improvement. Incorporating safety drills into routine training can help ensure that everyone is prepared for emergencies. Finally, fostering a culture of safety where workers feel comfortable discussing their concerns can lead to a safer and more efficient workplace.

- Always conduct a risk assessment before handling drums to identify potential hazards in the workspace.

- Implement a safety checklist for drum handling that includes equipment inspection and area checks.

- Use proper lifting techniques, such as bending at the knees and keeping the back straight, to minimize injury risk.

- Establish clear signage in areas where drums are stored or handled to alert workers to potential hazards.

- Create a protocol for reporting safety issues or equipment malfunctions immediately.

- Ensure workers are trained in first aid and know emergency contact numbers for accidents.

- Maintain a first aid kit nearby for quick access in case of injuries during drum handling.

- Regularly review safety policies and make adjustments based on feedback and incident reports.

- Incorporate safety drills into routine training to ensure preparedness for emergencies.

- Encourage a culture of safety where workers feel comfortable discussing concerns related to drum handling.

3. Proper Use of Drum Handling Equipment

Using drum handling equipment correctly is essential for ensuring safety and efficiency in the workplace. Start by always reading and understanding the manufacturer’s instructions and safety guidelines before usage. This foundational step empowers operators to recognize the equipment’s capabilities and limitations. Moreover, it is vital that all operators are trained and authorized to use the equipment, as this knowledge minimizes risks and enhances operational effectiveness.

Selecting the right equipment for the job is another crucial aspect. For example, drum lifters are ideal for lifting drums vertically, while dollies are perfect for transportation. Always check the load capacity of your equipment to avoid overloading, as this can lead to serious accidents. Before lifting, securing the drum is a must to prevent any slips or falls during transport. If you’re using a forklift, ensure it is fitted with the appropriate drum handling attachments for safe operation.

Regular inspection of drum handling equipment for wear and tear is also critical. A quick visual check can save you from unexpected malfunctions. Keep your equipment clean and free from debris to maintain optimal performance. When operating powered equipment, be cautious around others to prevent accidents. Lastly, knowing the emergency shut-off procedures is vital should any malfunction occur. Following these practices ensures a safer and more efficient environment when handling drums.

4. Common Mistakes to Avoid When Handling Drums

Handling drums safely is crucial, yet many make simple mistakes that can lead to accidents. First and foremost, never try to lift a drum on your own if it’s too heavy; always ask for help or use appropriate equipment. Using makeshift tools is another common pitfall, as they can be unreliable and dangerous. Always pay attention to the labels on the drums, which provide essential information about their contents. Ignoring these warning signs could lead to hazardous situations. Additionally, dress appropriately by avoiding loose clothing or jewelry that could get caught in equipment while maneuvering drums.

When stacking drums, do so carefully and according to safety guidelines; haphazard stacking can cause falls and injuries. Take your time when handling drums; rushing often leads to mistakes. Ensure you distribute the weight evenly when lifting to maintain balance. Communication with coworkers is vital, especially in busy areas, to prevent accidents. Poor lighting can obscure hazards, so always check the visibility of your surroundings before handling drums. Lastly, don’t forget to report any near misses or unsafe conditions to management to help improve safety protocols.

5. Best Practices for Safe Drum Handling

To ensure safe and effective drum handling, following best practices is essential. Begin by promoting team lifting techniques, especially for heavy or awkwardly shaped drums. Encourage workers to use a buddy system, ensuring no one handles heavy drums alone. Establish designated areas for drum storage and handling, keeping the workspace organized and reducing risks. Training is crucial, teach employees to recognize signs of fatigue and promote regular breaks to prevent injuries. Utilize drum carts or skids for transporting drums over distances, making the process safer and more efficient. Familiarity with the facility layout, including emergency exits and equipment locations, is vital for all workers. Regularly review and practice emergency procedures so everyone is prepared for unexpected situations. For smaller drums, two-wheeled dollies can ease movement and reduce strain. Good housekeeping practices are also important; keep drum handling areas clutter-free and safe. Lastly, incorporate employee feedback into safety practices to continuously improve drum handling protocols.

6. Emergency Procedures for Drum Handling Accidents

Establishing a robust emergency response plan for drum spills or accidents is essential for any workplace handling drums. This plan should cover a variety of potential scenarios, ensuring that all workers are well-prepared to act swiftly and effectively. It’s crucial that every employee understands their specific roles during an incident, which can make all the difference in a crisis. Having readily available spill kits in areas where drums are handled allows for immediate action, minimizing damage and potential hazards.

Regular emergency drills are a must. These drills should include spill containment and evacuation procedures, helping to keep everyone sharp and ready. It’s also wise to maintain a list of emergency contacts that all workers can easily access, ensuring quick communication when needed. Providing training on the proper use of fire extinguishers and other safety equipment in drum handling areas is also vital, as it empowers workers to react confidently in emergencies.

Encourage a culture of reporting all incidents, regardless of how minor they may seem. This practice can help identify patterns and areas for improvement, leading to a safer work environment. A solid communication plan should be in place for notifying management and emergency services during serious incidents, allowing for a coordinated response. After any spill or leak, documentation and investigation are key to understanding what went wrong and preventing future occurrences. Regularly reviewing and updating emergency procedures based on incidents and feedback from staff ensures that your protocols remain effective and relevant.

Frequently Asked Questions

What are the most common mistakes people make when using drum handling equipment?

Some common mistakes include improper lifting techniques, neglecting to secure drums during transport, using the wrong equipment for the job, overlooking maintenance, and not following safety guidelines.

How can I ensure I’m using drum handling equipment safely?

To use drum handling equipment safely, always read and follow the manufacturer’s instructions, wear appropriate safety gear, inspect the equipment before use, and receive proper training on handling techniques.

What should I do if I notice my drum handling equipment is damaged?

If you notice any damage, immediately stop using the equipment, tag it to prevent accidental use, and report it to your supervisor. Get it repaired or replaced before using it again.

Why is regular maintenance important for drum handling equipment?

Regular maintenance is crucial because it helps identify wear and tear, prevents malfunctions, enhances safety, and extends the lifespan of the equipment, ensuring it operates effectively.

How can I train my team on proper drum handling techniques?

You can train your team through hands-on workshops, safety meetings, offering manuals, arranging demonstrations from experienced operators, and encouraging continuous learning about best practices.