When choosing a self-propelled dredge for your project, start with comprehensive research to understand your specific needs. First, evaluate the project scope, including size and depth of material being dredged. Make sure to identify the types of sediment involved, as different dredges excel at handling various materials like sand or clay. Environmental considerations are crucial too; you must ensure compliance with regulations to protect local ecosystems. Consider site conditions such as water depth and current speed that may affect accessibility. Lastly, think about operational efficiency, opt for equipment designed for maximum productivity and minimal downtime to keep your project on track.

1. Understanding Dredging Equipment

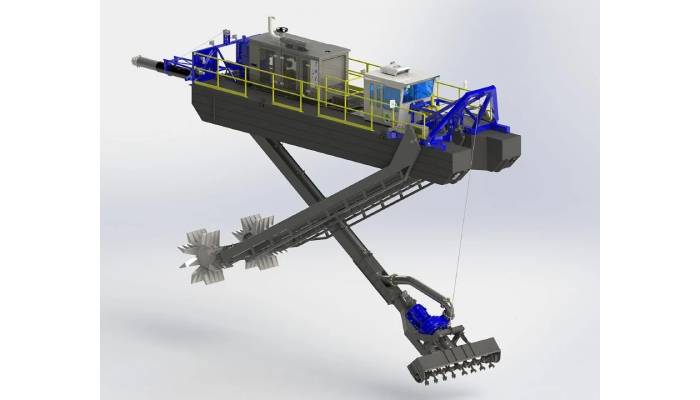

Self-propelled dredge equipment plays a vital role in excavating and transporting sediment from underwater environments. This machinery is essential for maintaining navigation channels, reclaiming land, remediating environmental damage, and extracting resources. Different types of dredges are designed for specific tasks, which can include everything from environmental cleanup to land reclamation. For instance, cutter suction dredgers use rotating cutter heads to loosen tough materials, while trailing suction hopper dredgers excel at removing loose sediment.

Understanding the components of dredging equipment, such as pumps and cutting heads, is crucial for efficient operation. Pumps are responsible for transporting the dredged material, and their performance directly affects the project’s productivity. Moreover, modern technology has led to advancements in dredging equipment, making it more efficient and environmentally friendly than ever before. For example, hydraulic systems enhance excavation efficiency and improve material transport, allowing projects to be completed faster.

It’s also important to recognize that dredging can significantly impact aquatic ecosystems. Therefore, the selection of equipment must be made with care to minimize ecological disruption. Safety features on dredging equipment are designed to protect operators and the surrounding environment, ensuring that projects can proceed without unnecessary risks. Additionally, operator training is vital to the safe and effective use of dredging equipment, as proper handling can significantly affect the project’s success. Regular maintenance and inspections of high-wear components are essential to keep equipment running smoothly and prolong its lifespan. As technology continues to evolve, innovations in dredging equipment are shaping the future of underwater excavation, promising more sustainable and efficient practices.

2. Key Factors to Consider When Choosing a Dredge

When selecting a self-propelled dredge, it’s crucial to evaluate the project scope first. This includes understanding the size, depth, and type of material that needs to be dredged. For instance, if your project involves soft silt, a cutter suction dredger might be more suitable than a bucket ladder dredger. Next, consider the sediment type; different dredges excel with various materials like mud, sand, or gravel. Choosing the right dredge can significantly impact efficiency and effectiveness.

Environmental considerations are also paramount. Before proceeding, assess the potential ecological impacts of your dredging method and ensure compliance with local regulations. Ignoring this can lead to costly delays or even project shutdowns. Additionally, understanding site conditions, such as water depth and current speed, helps determine the most appropriate equipment. For example, in fast-moving currents, a different dredge may be necessary compared to calm waters.

Operational efficiency plays a vital role in keeping your project on budget and on schedule. Pick equipment that maximizes productivity while minimizing downtime. Budget constraints are another key factor; balancing cost and capability is essential when selecting dredging equipment. Don’t overlook the availability of parts and support for the dredge, as this can help minimize downtime during operations.

Review past performance on similar projects to guide your decision-making. This insight can provide valuable information about what works best in comparable situations. Finally, consider the ease of transportation and setup of the dredging equipment on-site. Complex setups can lead to delays, so a dredge that is easy to transport and deploy can save time and headaches. Consulting with experts or conducting thorough site assessments will further enhance your decision-making process, ensuring you choose the best dredge for your specific project.

- Evaluate the project scope to determine the appropriate dredge type and size for your needs.

- Consider sediment type, as different dredges perform better with specific materials like mud, sand, or gravel.

- Assess environmental regulations and potential impacts before selecting a dredging method.

- Understand site conditions including water depth and current speed, which can influence equipment choice.

- Operational efficiency ensures that the dredging process is cost-effective and timely.

- Budget constraints should guide the selection of dredging equipment, balancing cost and capability.

- Look into the availability of parts and support for the dredging equipment to minimize downtime.

- Review past performance history of similar dredging projects to inform your decision.

- Consider the ease of transportation and setup for the dredging equipment on site.

- Consult with experts or conduct site assessments to make an informed choice.

3. Types of Self-Propelled Dredges

Self-propelled dredges come in several types, each designed for specific tasks and environments. Cutter Suction Dredgers (CSD) are incredibly versatile; they use rotating cutter heads to tackle tough materials, making them perfect for projects where sediment types vary or are particularly stubborn. On the other hand, Trailing Suction Hopper Dredgers (TSHD) shine in handling loose materials, which makes them a go-to choice for large-scale projects like land reclamation or maintaining navigation channels.

Excavator Dredgers are ideal for confined spaces, offering precise dredging capabilities that are essential for smaller, specialized tasks. Grab Dredgers, or clamshells, excel at targeted material removal, making them excellent for cleanup operations where specific debris needs to be extracted without disturbing the surrounding area. Bucket Ladder Dredgers work continuously, utilizing chains to extract compact materials reliably, which is particularly useful in environments where traditional suction methods may falter.

Each dredge type has unique strengths and weaknesses based on the project’s needs and the environment it operates in. Some advanced models can switch between dredging methods, providing flexibility to adapt to changing conditions. With features like GPS and automation, modern dredges enhance operational efficiency, allowing for more accurate and easier maneuvering. Understanding these various types is crucial for selecting the right dredge for your project.

4. Factors Influencing Dredging Technique Selection

Material composition plays a significant role in determining the right dredging technique. For instance, softer materials like silt may require a different approach than harder materials such as clay or gravel, which can be challenging to excavate. The level of pollution in the area also greatly influences the choice of dredging technique. In contaminated sites, special methods need to be employed to ensure that the dredging process does not spread pollutants further into the environment.

The size and volume of the project are crucial factors as well. Larger projects demand more robust dredging equipment and efficient logistics for transporting the dredged material. Moreover, minimizing spillage and opacification is vital for protecting water quality during dredging. Techniques that help limit the release of suspended particles into the water are often prioritized.

In addition, the presence of underwater structures, such as pipelines or natural formations, can restrict the choice of dredging methods and equipment. It’s also essential to consider client specifications and project deadlines, which can add pressure to the selection process. Evaluating the cost-effectiveness of different techniques ensures that the project stays within budget while meeting all operational requirements.

Local regulations may impose specific guidelines that can shape the choice of dredging techniques. Conducting thorough environmental impact assessments is often necessary, as these evaluations guide the selection process and help ensure compliance with legal and ecological standards. Finally, collaborating with engineers and environmental specialists can lead to more informed decisions, optimizing both effectiveness and sustainability in dredging projects.

6. Advanced Technologies in Dredging

Advanced technologies are transforming the dredging industry, making operations more efficient and environmentally friendly. Automation in dredging technology allows for precise excavation, reducing human error and increasing productivity. For instance, automated dredgers can operate continuously, optimizing time and resources. The integration of GPS technology is another game-changer, enabling real-time mapping and monitoring of dredging activities. This ensures that dredging operations are conducted exactly where needed, minimizing waste and enhancing accuracy.

Safety is paramount in dredging, and remote control capabilities are a significant advancement. Operators can manage dredging equipment from a safe distance, which is particularly beneficial in hazardous environments. Eco-friendly technologies are also on the rise, focusing on reducing carbon emissions and energy consumption, thus aligning with global sustainability goals.

Moreover, data analytics plays a vital role in modern dredging. By analyzing performance metrics, operators can identify areas for improvement, enhancing operational efficiency. 3D modeling and simulation techniques allow for detailed planning and visualization of projects before execution, mitigating risks and ensuring that all aspects are considered.

Innovative materials in dredging equipment construction improve durability, helping to reduce maintenance needs and prolong the lifespan of the machinery. Wireless communication systems enable better coordination among team members during operations, ensuring that everyone is on the same page. Smart sensors are another innovation, capable of monitoring dredging conditions and equipment performance, alerting operators to potential issues before they escalate. Continuous research and development in dredging technologies promise to further revolutionize the industry, paving the way for even more exciting advancements in the future.

Frequently Asked Questions

What are self-propelled dredges and how do they work?

Self-propelled dredges are specialized boats that can dig and move material from the bottom of rivers, lakes, or other bodies of water, using various tools like scoops or suction pumps. They are designed to navigate and operate on their own without the need for towing.

What factors should I consider when selecting a self-propelled dredge?

When choosing a self-propelled dredge, consider the size of your project, the type of material you need to move, the dredge’s capacity, and the environment where it will operate. Additionally, think about the ease of operation and maintenance of the dredge.

How does the dredging depth affect my selection of a self-propelled dredge?

The dredging depth is crucial because not all self-propelled dredges can operate at deep or shallow levels. Ensure you select a dredge that matches the depth of your project to maximize efficiency and effectiveness in material removal.

Are there different types of self-propelled dredges?

Yes, there are various types of self-propelled dredges, such as cutter suction dredges, hopper dredges, and trailing suction dredges. Each type has unique features suitable for different projects, so it’s important to understand the specific benefits of each type.

What maintenance should I expect for a self-propelled dredge?

Regular maintenance for a self-propelled dredge typically includes checking the engine, inspecting the dredging equipment, cleaning filters, and monitoring electronics. Proper maintenance ensures the dredge operates smoothly and can extend its operational life.