In the dredging industry, operational efficiency and safety go hand in hand. One of the most significant innovations in recent years is the Self-Propelled Dredge a versatile, mobile solution that has redefined the way dredging projects are executed. While these machines are praised for their speed, maneuverability, and productivity, their safety benefits are equally valuable, reducing risks to personnel, equipment, and the surrounding environment.

This article explores the core safety advantages of self-propelled dredging equipment, why they matter to operators and project managers, and how they compare to conventional dredging systems.

1. Understanding Self-Propelled Dredges

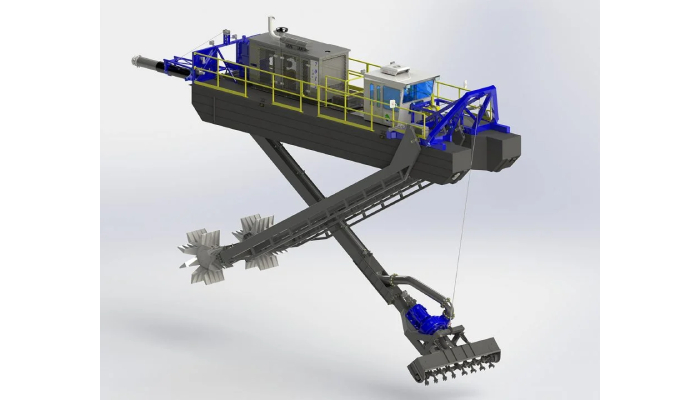

A Self-Propelled Dredge is a dredging vessel equipped with its own propulsion system, allowing it to move independently without needing tugboats or auxiliary transport. Unlike stationary dredges that require towing or anchoring systems, self-propelled models can navigate between sites, reposition quickly, and respond to changing project demands on their own.

Common types include:

- Cutter suction self-propelled dredges – for breaking and removing compacted materials.

- Trailing suction hopper dredges (TSHDs) – for large-scale sediment removal and transport.

- Multi-function amphibious dredges – for shallow water and marshy conditions.

While mobility is the most obvious advantage, the built-in propulsion system introduces several safety-related benefits that are worth examining in depth.

2. Reduced Dependence On Tugboats And Support Vessels

Traditional dredges often require tugboats for positioning, transport, or relocation, which introduces several safety challenges:

- Multiple vessels in close quarters increase collision risks.

- Crew coordination issues can arise when operating separate teams on different vessels.

- Adverse weather dependency makes towing operations riskier.

With a Self-Propelled Dredge, these risks are reduced because:

- The dredge can maneuver on its own, eliminating complex multi-vessel operations.

- Operators have direct control over positioning, reducing miscommunication hazards.

- Quick self-relocation in emergencies (such as sudden storms) improves crew safety.

3. Improved Emergency Response And Evacuation Capability

In dredging operations, emergencies can occur unexpectedly—from sudden mechanical failures to severe weather events. A Self-Propelled Dredge enhances safety through:

- Rapid Self-Movement – The ability to leave a danger zone without waiting for external assistance.

- Independent Navigation – Avoids delays associated with scheduling or locating support vessels.

- Better Storm Preparedness – The dredge can be quickly moved to sheltered waters, protecting both crew and equipment.

For example, during coastal dredging in cyclone-prone regions, the self-propulsion feature allows operators to evacuate to safe harbor within hours instead of days.

4. Enhanced Stability And Control

Modern self-propelled dredges are designed with advanced navigation systems, thrusters, and dynamic positioning (DP) technology. These features provide:

- Precise positioning even in strong currents or winds.

- Reduced anchor handling risks, which can be dangerous in deep or obstructed waters.

- Minimized risk of grounding or drifting, a common hazard for stationary dredges when mooring fails.

From a safety standpoint, the ability to maintain stable positioning without extensive mooring operations means fewer crew members are exposed to physically demanding and hazardous tasks on deck.

5. Lower Risk Of On-Water Transfers

In conventional dredging setups, crews often have to board from smaller service boats or make transfers between vessels—operations that carry high accident potential. A Self-Propelled Dredge:

- Operates as a self-contained unit, reducing the need for risky crew transfers.

- Allows direct boarding from dock or shoreline in many cases.

- Minimizes personnel exposure to open water hazards.

Fewer transfer operations mean fewer opportunities for slips, trips, falls, and accidental immersion.

6. Streamlined Operations In Hazardous Environments

Some dredging locations pose additional dangers—such as contaminated sediment, extreme cold, high tidal ranges, or restricted waterways. A Self-Propelled Dredge improves safety in these challenging environments by:

- Reducing the number of support vessels and crew on site, lowering exposure levels.

- Limiting manual handling of anchors, winches, and ropes in dangerous conditions.

- Navigating in tight areas without tug assistance, minimizing collision risks with shore structures or other vessels.

7. Better Crew Accommodation And Working Conditions

Modern self-propelled dredges are often outfitted with on-board living quarters, climate control, and safety facilities. This integration:

- Reduces fatigue by allowing crews to remain on the dredge rather than commuting by boat daily.

- Improves morale and alertness—key factors in accident prevention.

- Provides immediate access to first aid and emergency response equipment.

A rested and well-equipped crew is less prone to human error, which remains one of the biggest contributors to marine accidents.

8. Reduced Anchoring And Mooring Hazards

Traditional dredges may need frequent anchoring, which can be labor-intensive and dangerous in poor weather or fast currents. Risks include:

- Snap-back from tensioned cables.

- Crushing injuries during anchor handling.

- Equipment damage from dragging anchors.

Because Self-Propelled Dredges can hold position using thrusters or DP systems, anchor use is minimized, leading to:

- Less manual handling of heavy gear.

- Fewer deck accidents.

- Shorter exposure to hazardous deck operations.

9. Compliance With Modern Safety Standards

Self-propelled dredging equipment is often designed with International Maritime Organization (IMO) and Occupational Safety and Health Administration (OSHA) safety compliance in mind. This means:

- Integrated fire suppression systems.

- Enclosed control cabins for protection against weather and noise.

- Redundant power and propulsion systems for emergency backup.

- Advanced navigation aids to reduce collision risks.

These built-in compliance features not only protect the crew but also help operators meet legal safety obligations, avoiding costly penalties.

10. Case Example: Coastal Dredging In High-Traffic Waters

Imagine a dredging project in a busy commercial harbor. A conventional stationary dredge would require:

- Tug assistance for repositioning between work zones.

- Constant coordination with port authorities.

- Additional crew on multiple vessels.

A Self-Propelled Dredge streamlines this scenario:

- The vessel moves itself when instructed by harbor traffic control.

- Emergency repositioning happens instantly if large ships approach.

- Crew exposure to moving between vessels is nearly eliminated.

In this environment, the self-propelled model not only improves efficiency but directly reduces collision and transfer hazards.

11. Environmental Safety As An Extension Of Crew Safety

Safety isn’t only about protecting people—protecting the environment can also reduce indirect risks to workers. Self-propelled dredges:

- Spend less time in transit, lowering spill risks.

- Require fewer anchor drops, reducing seabed disturbance.

- Can leave hazardous areas faster in case of chemical or fuel spills.

This capability ensures dredging projects meet environmental regulations while safeguarding workers from exposure to dangerous contaminants.

Conclusion

A Self-Propelled Dredge is more than a mobile dredging machine—it’s a safer, more self-sufficient platform that reduces operational hazards, minimizes crew exposure to risky situations, and enhances emergency response capabilities. By eliminating the need for constant tug support, reducing on-water transfers, and incorporating modern safety technology, these vessels set a new standard in dredging safety.