When it comes to controlling fluid and gas flow in industrial applications, butterfly valve manufacturers play a critical role in providing reliable and efficient solutions. Whether you’re working in water treatment, HVAC systems, chemical processing, or oil and gas industries, choosing the right butterfly valve can significantly impact your operation’s performance and cost-effectiveness. This comprehensive guide will help you understand what makes butterfly valves essential components and how to select the perfect manufacturer for your specific needs.

What Is a Butterfly Valve Manufacturer and Why Are They Important?

A butterfly valve manufacturer is a company that designs and produces butterfly valves – specialized flow control devices used across numerous industries. These manufacturers combine engineering expertise with advanced manufacturing processes to create valves that meet stringent quality standards and performance requirements. The importance of selecting a reputable butterfly valve manufacturer cannot be overstated, as the quality of these components directly affects your system’s reliability, efficiency, and operational costs.

Butterfly valves are preferred in many applications because they offer quick shut-off capabilities, compact design, and cost-effective solutions compared to other valve types. Manufacturers specializing in butterfly valves have perfected the art of producing these devices with precision engineering that ensures minimal leakage, smooth operation, and extended service life. When you partner with an experienced butterfly valve manufacturer, you’re investing in technology that has been tested and refined across thousands of industrial installations.

The manufacturing process itself is sophisticated, involving precise machining, quality testing, and compliance with international standards. Leading butterfly valve manufacturers maintain rigorous quality control procedures throughout production, from material selection to final inspection. This dedication to quality ensures that every valve leaving their facility meets or exceeds industry specifications.

Understanding Butterfly Valve Types and Their Applications?

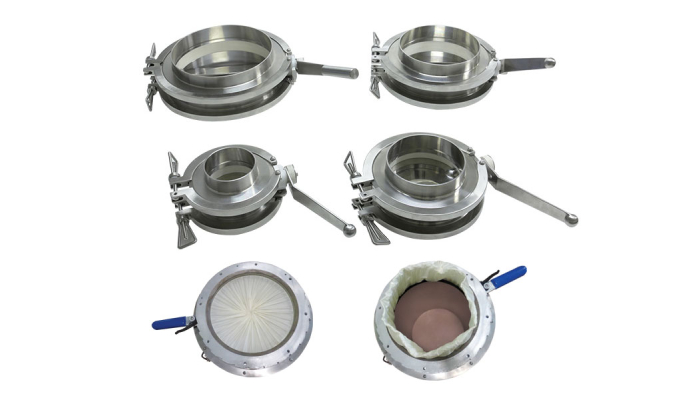

Butterfly valve manufacturers produce several distinct types of valves, each designed for specific applications and operating conditions. The most common types include wafer-style, lug-style, and flanged-style butterfly valves. Wafer-style valves are lightweight and compact, making them ideal for applications where space is limited. Lug-style valves feature threaded inserts on both sides, allowing installation between pipe sections with bolts. Flanged-style valves are equipped with flanges for direct connection to piping systems.

Each type serves different purposes depending on your system requirements. Wafer-style valves work well in low-pressure applications, while lug-style valves offer better support in medium to high-pressure systems. Experienced butterfly valve manufacturers understand these distinctions and help customers select appropriate options. The material composition also varies – manufacturers offer valves in ductile iron, stainless steel, aluminum bronze, and other materials depending on the fluid being handled and environmental conditions.

Applications range from simple water distribution systems to complex industrial processes. Food and beverage industries rely on sanitary butterfly valves, pharmaceutical companies require FDA-compliant models, and power plants need heavy-duty variants capable of handling extreme temperatures and pressures. Leading manufacturers maintain specialized product lines addressing these diverse needs.

How Do Butterfly Valve Manufacturers Ensure Quality and Reliability?

Quality assurance is paramount for reputable butterfly valve manufacturers. These companies implement comprehensive testing protocols including pressure testing, seat leakage testing, and operational cycle testing to verify performance before shipment. Many manufacturers maintain ISO 9001 certification and comply with international standards such as API, ASME, and DIN specifications.

Manufacturers invest in state-of-the-art inspection equipment and employ experienced quality control specialists who meticulously examine each component. Materials undergo rigorous testing to confirm they meet specified compositions and mechanical properties. The manufacturing facility itself must maintain strict environmental controls and cleanliness standards to prevent contamination.

Reputable butterfly valve manufacturers also provide comprehensive documentation including material certifications, test reports, and technical specifications. This transparency allows engineers to make informed decisions based on complete product information. Many manufacturers offer warranty coverage on their products, demonstrating confidence in their quality and workmanship.

Key Factors When Selecting a Butterfly Valve Manufacturer?

Selecting the right butterfly valve manufacturer requires careful consideration of several factors. First, evaluate the manufacturer’s reputation and track record in your specific industry. Look for companies with extensive experience serving similar applications and proven success with comparable systems. Check references from current customers and review case studies demonstrating successful installations.

Second, assess the manufacturer’s technical capabilities and customer support. Do they have engineering staff who can provide guidance on valve selection? Can they accommodate custom specifications if needed? Will they offer technical support throughout the installation process? Leading manufacturers stand ready to answer questions and provide solutions.

Third, consider manufacturing capacity and lead times. Ensure the manufacturer can meet your quantity requirements within acceptable timeframes. Supply chain reliability matters significantly – a manufacturer unable to deliver on schedule can disrupt your projects. Finally, evaluate pricing competitively but remember that the lowest cost isn’t always the best value. Factor in quality, support, and long-term reliability when comparing options.

Latest Innovations in Butterfly Valve Manufacturing?

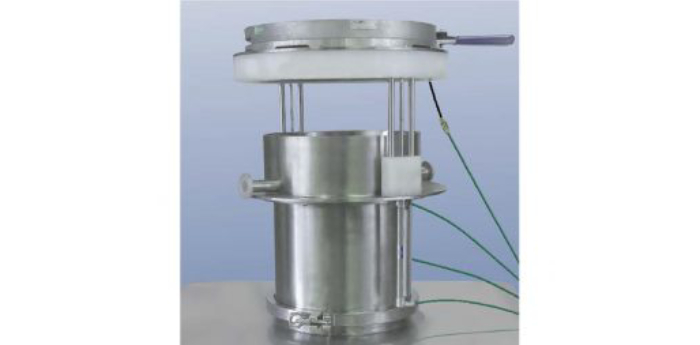

Modern butterfly valve manufacturers continuously innovate to improve performance and functionality. Recent advancements include improved sealing technologies that reduce leakage rates to near-zero levels. Some manufacturers now offer smart valves equipped with sensors and IoT connectivity, enabling remote monitoring and predictive maintenance. These innovations help operators track valve performance in real-time and address issues before they become critical problems.

Manufacturers are also developing environmentally friendly designs using sustainable materials and reducing manufacturing waste. Advanced coating technologies extend valve lifespan and improve resistance to corrosion and wear. Some companies are experimenting with composite materials that offer improved performance characteristics while reducing weight.

Digital design tools allow manufacturers to simulate valve performance under various conditions before physical production, resulting in more efficient designs. Additive manufacturing techniques are beginning to play a role in producing specialized components, enabling customization previously impossible through traditional manufacturing methods.

Making Your Final Decision: Choosing the Right Butterfly Valve Manufacturer?

Your final decision should balance technical requirements, reliability considerations, and cost factors. Create a detailed specification sheet outlining your system’s requirements including pressure ratings, temperature ranges, flow rates, and chemical compatibility needs. Share this with multiple manufacturers and request detailed quotations including delivery timeframes. When evaluating responses, look beyond the price to assess overall value and capability. Many industries benefit from working with specialized valve manufacturers who understand their unique challenges and requirements. Whether you’re operating a municipal water system, managing an industrial processing plant, or maintaining HVAC infrastructure, the right manufacturer makes a significant difference.

The relationship with your butterfly valve manufacturer should extend beyond the initial purchase. Establish ongoing communication channels for technical support, spare parts availability, and maintenance guidance. Leading manufacturers view customers as long-term partners and invest in relationships that span decades.

Conclusion

Choosing the right butterfly valve manufacturer is a strategic decision that impacts your operation’s efficiency, reliability, and bottom line. By understanding valve types, quality standards, and selection criteria, you can make informed choices that serve your long-term interests. Prioritize manufacturers with strong reputations, comprehensive product offerings, and genuine commitment to customer success. The investment in quality and reliability pays dividends through reduced downtime, lower maintenance costs, and improved operational performance. Whether you need simple on-off control or sophisticated flow regulation, the perfect butterfly valve manufacturer exists to meet your specific requirements and support your success.

#ButterflyValveManufacturer #IndustrialValves