When buying a used diesel dredge, several factors should be carefully considered to make a smart investment. Start by investigating the seller’s reputation and stability in the industry. It’s crucial to conduct a thorough inspection of the dredge’s mechanical parts, looking for any signs of wear. Ensure that spare parts are readily available and inquire about any warranties offered on the equipment. Understand your budget, which should include potential repair costs and necessary additional equipment. Lastly, comparing different models will help you identify the best value while evaluating if refurbishment has been done properly can lead to reliable performance down the road.

1. Reputation and Stability of the Seller

When you’re on the hunt for a used diesel dredge, the seller’s reputation and stability should be at the top of your checklist. Start by digging into the seller’s history in the dredging industry; their experience level can provide insight into their reliability. Look for reviews and testimonials from previous customers, as these can give you a real sense of satisfaction levels. If the seller is a member of professional organizations or associations related to dredging, that’s a good sign of credibility.

Investigate their financial health as well, perhaps through credit reports or business ratings, to ensure they are stable enough to support you after the sale. Asking for references from past buyers can yield firsthand accounts of their dealings, helping you gauge how trustworthy they are. Longevity also matters; a seller who has been in business for years is often more reliable than a newcomer.

Consider whether the seller has a dedicated customer service team for ongoing support, as this can be crucial if you encounter issues later. Additionally, look into any past legal issues or complaints filed against them, red flags here could indicate problems. Evaluating the seller’s portfolio of dredges sold, paying attention to the types and models they specialize in, can also give you insight into their expertise. If possible, visit their facility to see their operations and inventory firsthand; this can solidify your confidence in your choice.

2. Inspection of Equipment Condition

When inspecting a used diesel dredge, start with a careful look for any visible signs of corrosion or rust, particularly on metal parts. These signs can indicate how well the dredge has been maintained. Then, check the engine for leaks, vibrations, or unusual noises during operation; any of these issues could point to serious problems. Don’t overlook the pump and suction hoses either; inspect them for wear or damage, as these components are vital for efficient dredging.

It’s also essential to examine the dredge’s hull for cracks or structural weaknesses, which could affect its performance and safety. Electrical systems should be scrutinized for frayed wires or faulty connections, as these can lead to operational failures. Evaluate the hydraulic systems thoroughly for leaks or pressure issues that might suggest underlying problems.

Pay attention to wear parts, such as cutter heads and screens; these are often subject to heavy wear and may need replacement soon. Reviewing maintenance logs is equally important, as they offer insights into whether the dredge has been regularly serviced. Lastly, check the condition of the tracks or wheels, as these components significantly influence mobility. Using a checklist during your inspection can help ensure that you cover all areas and don’t miss anything crucial.

- Inspect the dredge for visible signs of corrosion or rust, especially on metal parts.

- Check the engine for leaks, vibrations, or abnormal noises during operation.

- Examine the pump and suction hoses for signs of wear or damage.

- Look at the dredge’s hull for cracks or structural weaknesses.

- Inspect the electrical systems for frayed wires or faulty connections.

- Evaluate the hydraulic systems for leaks or pressure issues that might indicate problems.

- Check the condition of wear parts, such as cutter heads and screens, for necessary replacements.

- Review maintenance logs to see if the dredge has been regularly serviced.

- Pay attention to the condition of the tracks or wheels, as they affect mobility.

- Consider using a checklist during the inspection to ensure all areas are covered.

3. Service and Parts Availability

When buying a used diesel dredge, service and parts availability should be high on your list of priorities. Start by identifying the manufacturer of the dredge, as this will help you check for official parts availability. If the manufacturer is well-known, you will likely find a robust supply chain for essential components. Always inquire about the lead time for obtaining parts, since lengthy downtimes can cut into your productivity. It’s a good idea to ask the seller if they have contacts in their parts department or if they can provide supplier contacts for you to access.

Additionally, conduct online research to find common dredge parts and their availability in the aftermarket. Knowing which parts are critical for operation is essential; if they are hard to find, it could lead to costly delays. Check if there are local distributors or service centers that can provide quick repairs and support.

Understanding the design of the dredge is crucial too. If it features a common design, parts access will likely be easier. Look for equipment that has interchangeable parts with other models, as this can greatly enhance your flexibility. Finally, evaluate the seller’s commitment to providing ongoing support for parts after the sale, this can make a significant difference in your experience. Also, consider the potential need for custom parts and their availability, as this can affect your long-term operational strategy.

4. Cost of Additional Equipment

When purchasing a used diesel dredge, it’s essential to consider the cost of additional equipment that will be necessary for effective operation. This includes essential accessories like dredging hoses, floats, and tools that may not be included in the initial sale. For instance, if the dredge is sold without the hoses, you could face unexpected expenses that add up quickly. Inquire about the costs of these essentials and whether they are part of the package, as this could significantly impact your budget.

Transportation is another critical factor. If the dredge requires a trailer or tug for transport, factor in these costs as well. Having the right transportation equipment is crucial for moving your dredge to various job sites. Additionally, look into any upgrades that might be needed to maximize the dredge’s performance. For example, you might want to add more powerful pumps or better control systems, which can enhance productivity but also elevate your initial investment.

Optional attachments can also enhance your dredging capabilities. Research their prices and consider how they fit into your overall budget. Beyond operational needs, safety equipment like life vests, helmets, and first aid kits is vital. These items can be overlooked but are crucial for ensuring a safe working environment. Don’t forget about sediment disposal solutions as well; understanding the costs associated with disposing of dredged material can be just as important as the dredging process itself.

Ultimately, calculate the total cost of ownership, which includes all extra equipment and accessories. Comparing these costs with other dredges on the market will help you assess the overall value of your purchase. By being thorough in your evaluation of additional equipment costs, you can make a well-informed decision that aligns with your operational needs and budget.

5. Warranty and Guarantees

When purchasing a used diesel dredge, securing a solid warranty is essential for peace of mind. Always ask for a written warranty that clearly outlines the coverage terms and conditions. It’s important to understand how long the warranty lasts and what it specifically covers, such as parts and labor. Additionally, inquire if there are any guarantees regarding the dredge’s performance or condition, as this can significantly influence your confidence in the purchase.

Be sure to check for any exclusions in the warranty, which might include typical wear and tear or damage from misuse. If you plan to sell the dredge in the future, ask whether the warranty is transferable to the new owner, as this could add value to your resale.

It’s also wise to see if the seller offers any service contracts for ongoing maintenance, providing you with further reassurance about the dredge’s upkeep. Understanding how claims under the warranty are handled and the documentation required can save you from headaches later.

Researching the manufacturer’s warranty policy can uncover additional coverage options that might be available. Lastly, be aware of the implications of buying a dredge ‘as is’ without warranties; this could mean taking on all repair responsibilities. Overall, selecting a seller who offers strong guarantees can greatly enhance your buying experience.

6. Operation and Maintenance History

When buying a used diesel dredge, the operation and maintenance history is crucial. Start by requesting detailed logs of maintenance and repairs. These records will reveal how well the dredge has been cared for over the years. Look for documentation of routine servicing, which indicates proper upkeep. It’s important to know how frequently the dredge was used and the types of projects it handled, as this can impact its wear and tear. Inquire about any major repairs or replacements, along with their costs, to understand potential future expenses. Consider whether the dredge was operated by trained personnel, as misuse can lead to significant damage. Assess the overall operational hours, as they directly correlate with the equipment’s lifespan. Also, understanding the frequency of breakdowns can help identify reliability issues. Ask about any operational changes that might have affected the dredge’s performance, and look for documentation of upgrades or modifications. Finally, consider the age of the dredge in relation to its maintenance history to gauge any risks associated with its purchase.

7. Type of Dredge and Suitability

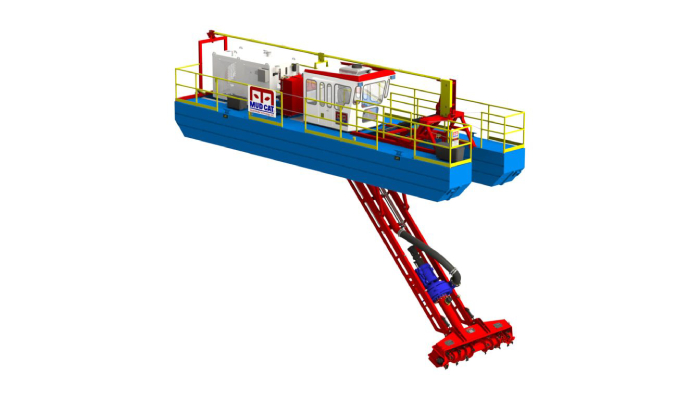

When buying a used diesel dredge, determining the type that aligns with your project needs is crucial. There are various dredge types, such as cutter suction and dredge barges, each designed for specific tasks. For instance, if your project involves moving sand, a cutter suction dredge may be ideal due to its effectiveness in cutting through compacted materials. Take the time to match the dredge’s capabilities with the sediment type you will be working with, as using the wrong equipment can lead to inefficiencies and increased operational costs. Additionally, evaluate the dredge’s capacity to manage your expected workload. Consider its depth capabilities too; if you need to dredge in deeper waters, ensure the dredge can reach those depths while maintaining efficiency.

It’s also essential to think about how adaptable the dredge is for future projects. Will it handle different materials or tasks if your project scope changes? Fuel consumption and operational costs are another vital factor, as a more efficient dredge can save you money in the long run. Don’t overlook mobility; assess how easily the dredge can be transported to various job sites. Lastly, research testimonials and case studies from past users to gauge its performance in real-world applications. Ensuring the dredge complies with local regulations for dredging materials is also a must, as this can prevent legal issues down the road.

8. Inspection by a Professional

Hiring a qualified technician to inspect a used diesel dredge is a crucial step in the buying process. Look for someone with specialized experience in dredge inspections, as they will know what to look for in both operational and safety aspects. Before the inspection, discuss any specific concerns you have, ensuring the technician is aware of what you want them to focus on. After the inspection, request a comprehensive report detailing their findings, which can reveal hidden issues that may not be immediately obvious. It’s also wise to inquire about the technician’s credentials and past experience with similar equipment, as this can give you confidence in their assessment.

Don’t forget to ask for a follow-up consultation to review the findings and recommendations. This conversation can be immensely helpful in understanding any potential repairs or modifications needed. Weigh the cost of the inspection against the potential savings you might gain by avoiding a poor purchase. If you receive differing results from multiple inspections, consider seeking a second opinion. Additionally, a good technician can offer insights about possible upgrades or modifications that could enhance the dredge’s performance. Finally, request a certification or guarantee of the inspection for your records, providing peace of mind as you make this important investment.

9. Budget Considerations

Setting a clear budget is crucial when buying a used diesel dredge. Start by determining the purchase price but remember to account for additional costs like taxes, registration fees, and transportation expenses. Long-term operational costs also play a significant role in your budget. Fuel, repairs, and routine maintenance can add up quickly, so it’s wise to factor these into your overall financial plan. If you’re considering financing options, understand the implications of taking out a loan, including interest rates and payment terms.

Don’t overlook the potential resale value of the dredge; it can significantly impact your long-term financial strategy. If you plan to sell it down the line, choosing a model known for retaining value can be a smart move. Hidden costs can sneak up on you, so be thorough in your research. Evaluate if investing in newer equipment might save you money in the long run, as it could lead to fewer repairs and lower operational costs.

Training for personnel is another expense that shouldn’t be ignored. Ensure that your team is well-prepared to operate and maintain the dredge, as this can prevent costly mistakes. It’s also wise to be realistic about unexpected expenses. Setting aside a contingency fund can provide peace of mind for any surprises that come your way. Regularly review your budget to adjust for changes in your project needs or economic conditions. Collaborating with a financial advisor familiar with equipment purchases can help you navigate this complex landscape and ensure that your investment is sound.

10. Comparison Shopping

When it comes to buying a used diesel dredge, comparison shopping can be your secret weapon. Start by creating a list of dredges that fit your desired features and budget. Once you have this list, use side-by-side comparisons to evaluate their specifications, such as engine performance, pump capacity, and overall condition. Don’t just stop at the dredges themselves; research various sellers to compare prices and services they offer.

If you can, attend trade shows or exhibitions, as these events allow you to see dredges in person, helping you gauge the quality and functionality firsthand. Don’t hesitate to reach out to multiple sellers to negotiate better terms or even discounts. Keep an eye out for promotional offers or financing plans that could significantly impact your overall costs.

Reading reviews and gathering feedback from current users is invaluable. Their experiences can reveal hidden strengths or weaknesses in different models. Additionally, assess the warranty and service options each seller provides; a solid warranty can save you headaches and expenses down the line.

Lastly, remember to evaluate the total cost of ownership, which includes not just the purchase price but also maintenance and operational expenses. Staying organized is key, so document all your comparisons for easy reference during your decision-making process.